Corrugated packaging has had a profound impact on the world and the way we do business. Countless industries and business models would not be possible without access to this effective, yet inexpensive, type of packaging. Corrugated boxes do a great job at protecting an item through the shipping and handling process.

Did you know that approximately 95% of corrugated produced is recovered for recycling? The recovered corrugated is used to make new products making corrugated packaging one of the most cost effective and environmentally friendly packaging solutions.

One important factor to consider when starting any corrugated project is choosing the correct corrugated board. There are two types of corrugated board: Mullen and ECT. Not every company can provide both options, so it is good for you to understand the difference and what is needed for your application.

What is Mullen grade board?

Mullen grade board is mainly comprised of virgin material as opposed to recycled material. This means that the fibers within the corrugated are longer and interwoven. Because of this, mullen corrugated board is generally considered more robust and durable. Higher levels of virgin material also mean that mullen is slightly more expensive than the ECT equivalent.

Mullen grade board is certified by using a test known as the Burst (or “Mullen”) test to determine its strength. The burst test uses hydraulics to slowly put pressure on the flat side of a corrugated sample until the sample breaks or “bursts”. This test determines the structural strength of the material. Mullen grade board is measured in pounds (per square inch). Common Mullen measurements include 200#, 275#, and 350#. The higher the unit number, the more pounds per square inch the corrugated board can hold. Therefore, the higher the # number, the stronger the corrugated.

What is ECT grade board?

ECT grade board is mostly comprised of recycled material. The recycled material, by nature, must be broken down and reformed to be used again. This process causes the fibers to become shorter and less interwoven, which is why ECT board is typically less sturdy and lighter than Mullen board. The main benefit to ECT vs. Mullen corrugated is that it costs less while providing comparable stacking strength.

As the business environment has become more automated, stacking corrugated boxes onto pallets has become common practice. This created a challenge for companies: The corrugated boxes on the bottom of the stack were always getting crushed. The industry needed a new way to evaluate stacking strength. Thus, the ECT or Edge Crush Test was born!.

ECT corrugated uses a different test to the determine the strength. The ECT test applies force to the fluted edge of a corrugated sample until the edges start to crack or get crushed. This measures the stacking strength of the corrugated. Common ECT measurements are 32 ECT, 44 ECT, and 48 ECT. Like Mullen board, the higher the unit number, the stronger the corrugated.

Do I use Mullen or ECT corrugated?

When trying to determine which board to use, there are a few questions to consider:

- Are the boxes going to be stacked? If so, how much weight will be on the bottom row?

- Will the boxes be shipped individually through parcel shipping service?

- How much does the item weigh going inside the box?

- How fragile or breakable is the item?

- Will there any additional cushioning, padding, or protection inside of the box?

- What other shipping and handling processes will the corrugated package be subject to?

These are just a few questions to consider when planning your next corrugated project. There are many factors to consider when designing optimal corrugated packaging. Contact PAX Solutions to ensure your next corrugated project is successful.

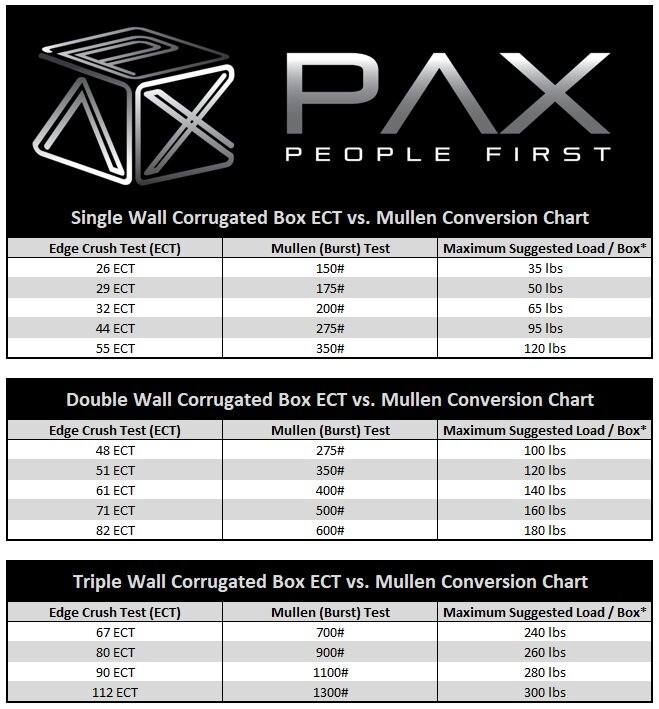

Pax Solutions provides both ECT and Mullen corrugated packaging. This is an often overlooked detail in the corrugated packaging design process, but we at PAX Solutions think our customers need to know about this! The conversion chart below shows the standard conversion between ECT and Mullen corrugated and the max suggested load per box. *Maximum suggested load/box is an estimate.