Embarking on a New Packaging Project: An 11 Step Guide

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

Flexible packaging has been a transformative force in the packaging industry offering a variety of benefits that enhance product branding and market viability. Known for its versatility, this packaging solution is engineered to provide superior protection, extended shelf life, and remarkable customization opportunities regarding size, shape, and printing. As consumer preferences shift towards more sustainable and convenient packaging offerings, flexible packaging solutions continue to evolve providing options that reduce environmental impact and improve the customer experience.

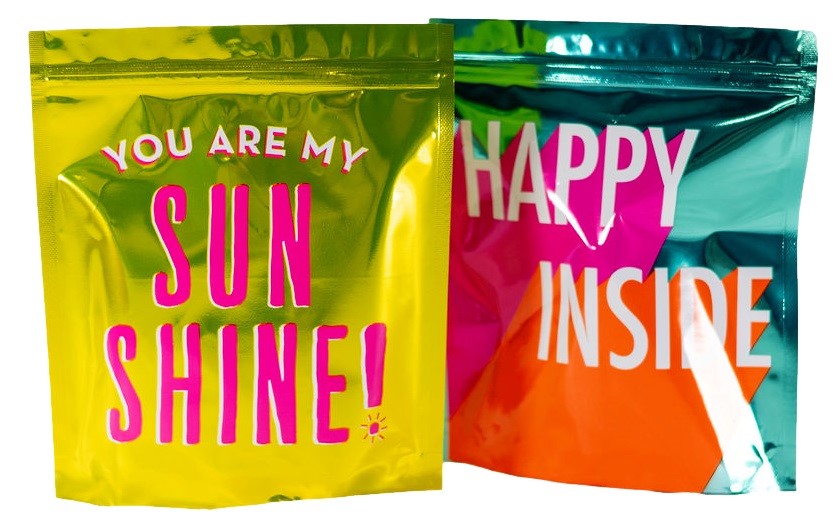

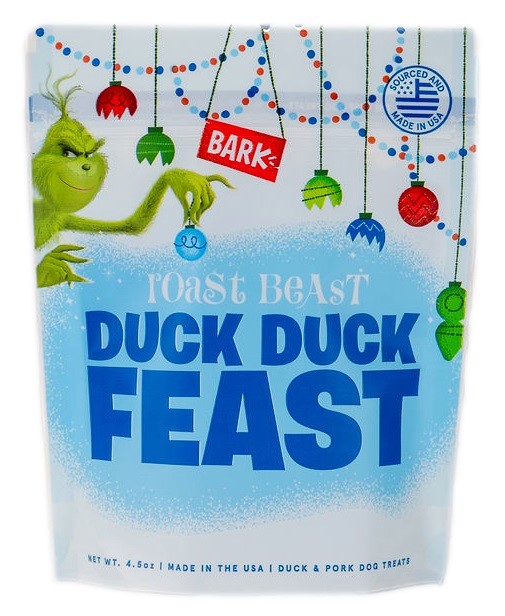

For brands looking to elevate their shelf presence and perceived value, flexible packaging offers a dynamic blank canvas for high-impact visuals and innovative packaging design. Advanced printing technologies enable vivid graphics, unique finishing embellishments, while also conveying a consistent brand message. As the marketplace becomes more crowded, utilizing the correct packaging solutions for your different products becomes increasingly important to remain competitive. Flexible packaging can be a great tool in your go-to-market strategy if used correctly. Contact Us to speak with our experienced team for your next corrugated packaging project.

We respond fast! Please complete the form below and our team will contact you shortly.

Flexible packaging offers superior product protection bolstering material that is resilient to punctures and tearing. Its multilayer structure provides a robust barrier against moisture, oxygen, and light, preserving the integrity of the product(s) inside.

With advancements in printing technology, flexible packaging can incorporate complex and detailed graphic designs that do not fade or wear over time. This longevity ensures that the packaging remains attractive and functional throughout the lifetime of the product, maintaining brand integrity and customer trust.

Continuous development of biodegradable and recyclable materials in flexible packaging represents significant leaps forward towards sustainability. These innovations in flexible material minimize waste and facilitate a circular economy, helping companies meet their commitments to eco-friendly products.

Flexible packaging is engineered to extend product shelf life by providing superior barrier properties against moisture, oxygen, and light, all of which are key factors that contribute to product degradation. This ability to maintain product freshness and quality for longer periods reduces waste, increases efficiency, and enhances customer satisfaction.

The versatility of flexible packaging allows for a variety of shapes and sizes enabling brands to optimize packaging volume lowering transportation, warehousing, and handling costs. This also allows for optimal material efficiency that streamlines supply chain operations and aligns with sustainability objectives by minimizing packaging material consumption.

Flexible packaging offers superior product protection bolstering material that is resilient to punctures and tearing. Its multilayer structure provides a robust barrier against moisture, oxygen, and light, preserving the integrity of the product(s) inside.

With advancements in printing technology, flexible packaging can incorporate complex and detailed graphic designs that do not fade or wear over time. This longevity ensures that the packaging remains attractive and functional throughout the lifetime of the product, maintaining brand integrity and customer trust.

Continuous development of biodegradable and recyclable materials in flexible packaging represents significant leaps forward towards sustainability. These innovations in flexible material minimize waste and facilitate a circular economy, helping companies meet their commitments to eco-friendly products.

Flexible packaging is engineered to extend product shelf life by providing superior barrier properties against moisture, oxygen, and light, all of which are key factors that contribute to product degradation. This ability to maintain product freshness and quality for longer periods reduces waste, increases efficiency, and enhances customer satisfaction.

The versatility of flexible packaging allows for a variety of shapes and sizes enabling brands to optimize packaging volume lowering transportation, warehousing, and handling costs. This also allows for optimal material efficiency that streamlines supply chain operations and aligns with sustainability objectives by minimizing packaging material consumption.

Selecting the right flexible packaging materials is critical to the success of your product. With a variety of materials, each offering distinct benefits such as enhanced barrier properties, aesthetic versatility, and sustainability, the choice of packaging can significantly influence consumer perception and market performance. Flexible packaging material used for packaging is constructed from multiple layers of plastic film material. By combining different film materials and utilizing available coatings, brands have the ability to completely customize the material attributes and performance.

Whether you are packaging food, pharmaceuticals, or high-end consumer goods, PAX Solutions is equipped to help you navigate the complexities of material selection. Below are some of the common materials used in the flexible packaging Industry.

Yes, many flexible packaging materials can be recycled. However, the recyclability depends on the materials used and local recycling facilities capabilities. It’s advisable to consult local recycling guidelines to understand the specific recycling options available.

Flexible packaging can extend shelf life through excellent barrier properties that protect contents from moisture, oxygen, and contaminants. Advanced sealing technology and the use of protective atmospheres inside the packaging further preserve the product and maintain quality.

Flexible packaging is suitable for a wide range of products, including food, beverages, pharmaceuticals, household chemicals, and personal care items. Its protective features and barrier properties make it ideal for products requiring extended shelf life and robust protection.

Customization options for flexible packaging include a variety of sizes, shapes, and functional features like zippers, spouts, and resealable closures. High-quality graphic printing is also available to enhance brand visibility and consumer appeal.

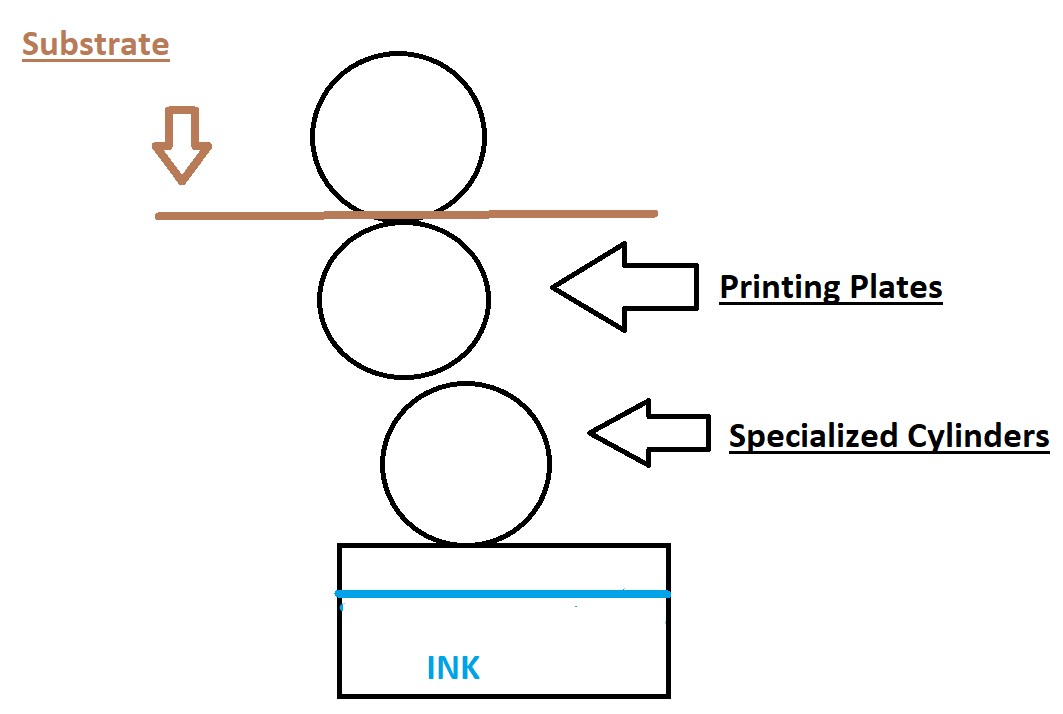

Flexible packaging often utilizes advanced printing technologies such as flexography, digital printing, and rotogravure. These methods allow for high-quality, vibrant, and detailed graphics that are essential for brand differentiation and consumer appeal on retail shelves.

Flexible packaging contributes to sustainability by requiring less energy to produce and transport, using fewer raw materials, and generating less waste compared to more rigid packaging formats. Additionally, innovations in biodegradable and recyclable materials are further enhancing the environmental benefits of flexible packaging.

Visit our PAX Solutions Blog to learn more about the fascinating world of packaging!

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

4- Color Process vs. PMS Coloring – What is the difference? Some of the most common questions when creating packaging

A great way to upgrade your packaging is through high quality print design. It can turn an average looking box

Copyright 2024, PAX Solutions, All Rights Reserved