What is Foil Stamping

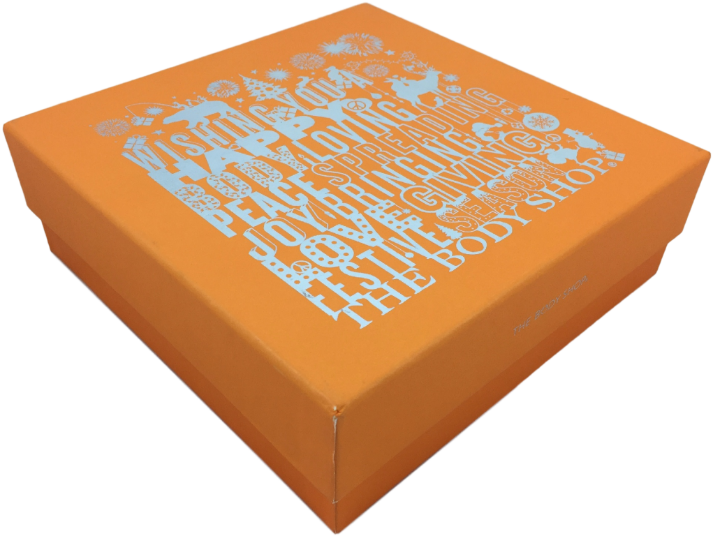

A great way to take your packaging to the next level and give it that luxurious feel is to add embellishments. One of the most popular embellishments you can add to your packaging is foil stamping. Foil stamping is an application method that uses heat and pressure to apply a foil to a material for a special finish. Foil stamping does not use standard printing ink; It is an impervious material, so it can stand out even on some of the darkest backgrounds. One of the most common foils used in this process is metallic foil, but there are also pearl foils, matte foils, holographic foils, and many more as mentioned below. The foils can come in a large variety of colors and finishes, so your design options are endless!

Types of Foils

• Metalized Foil: This is the standard foil material, which produces a shiny metallic finish. This material is available in a variety of colors, but gold and silver are the most popular options.

• Pearl Foil: These foils are used to add pearlescent shine to your design. They can be either transparent or translucent.

• Pigment Foil: Pigment foils do not have a metallic finish. They come in almost any color, with gloss or matte finish options. Pigment foils can be used on both paper and plastic substrates.

• Holographic Foil: This type of foil typically produces 3D effects or rainbow colored patterns. They are mainly used to increase aesthetics. Another cool application for holographic foil is security seals.

• Effects Foil: These are foils with multiple-colored patterns and tons. This could include stripes, sparkles, patterns, and anything that diffracts light.

Traditional Process of Foil Stamping

The first step in the foil stamping process is the design. The design is imprinted onto a metal plate, with each color having its own plate. The metal plate is then heated up and a thin layer of the foil is placed in between the metal plate and the substrate. As pressure to the metal plate is applied, it pushes or “stamps” the foil onto the substrate sealing the image onto the package. If you are using multiple colors it will have to run through the machine several times. Multiple colors and layers can make foil stamping a labor-intensive process.

Digital Revolution Hits Foil Stamping

Digital foil stamping, or digital foiling, has become increasingly popular in recent years. Throw those die costs away! Instead of using a stamping foil die to adhere the foil, digital foil printing is done using specialty inks that are digitally printed onto the packaging. Visually, digital foiling looks similar to traditional foiling.

Why Add Foil Stamping to Your Packaging

Foil stamping is an added expense to your standard packaging project, but most people find it a worthwhile investment to achieve a unique and enhanced design. It packs a big punch! And cool foil designs make a package stand out. Most often, consumers are also willing to pay more for a product when the packaging feels luxurious. Want to add foil stamping to your next project? Contact PAX Solutions to get started.