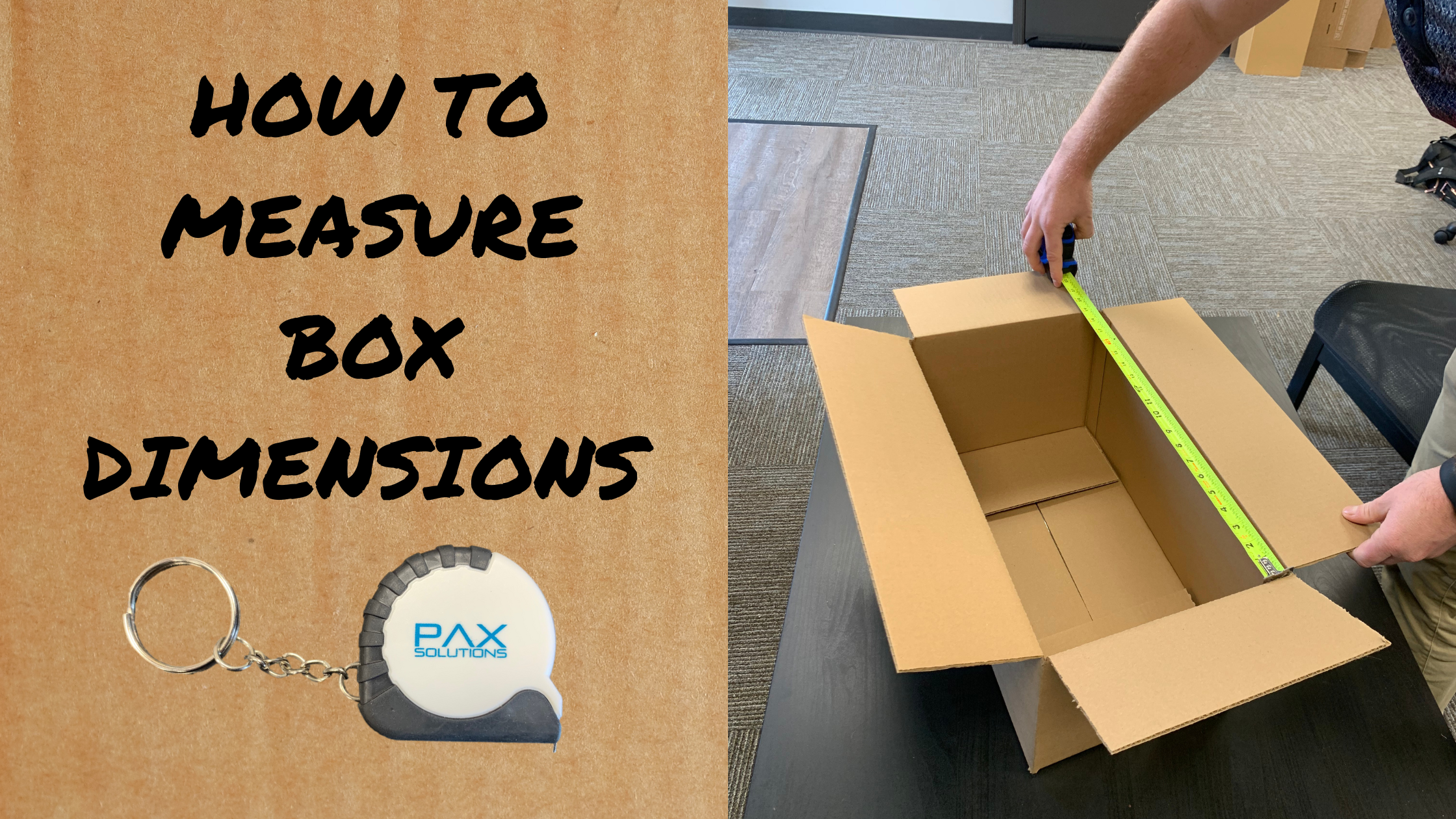

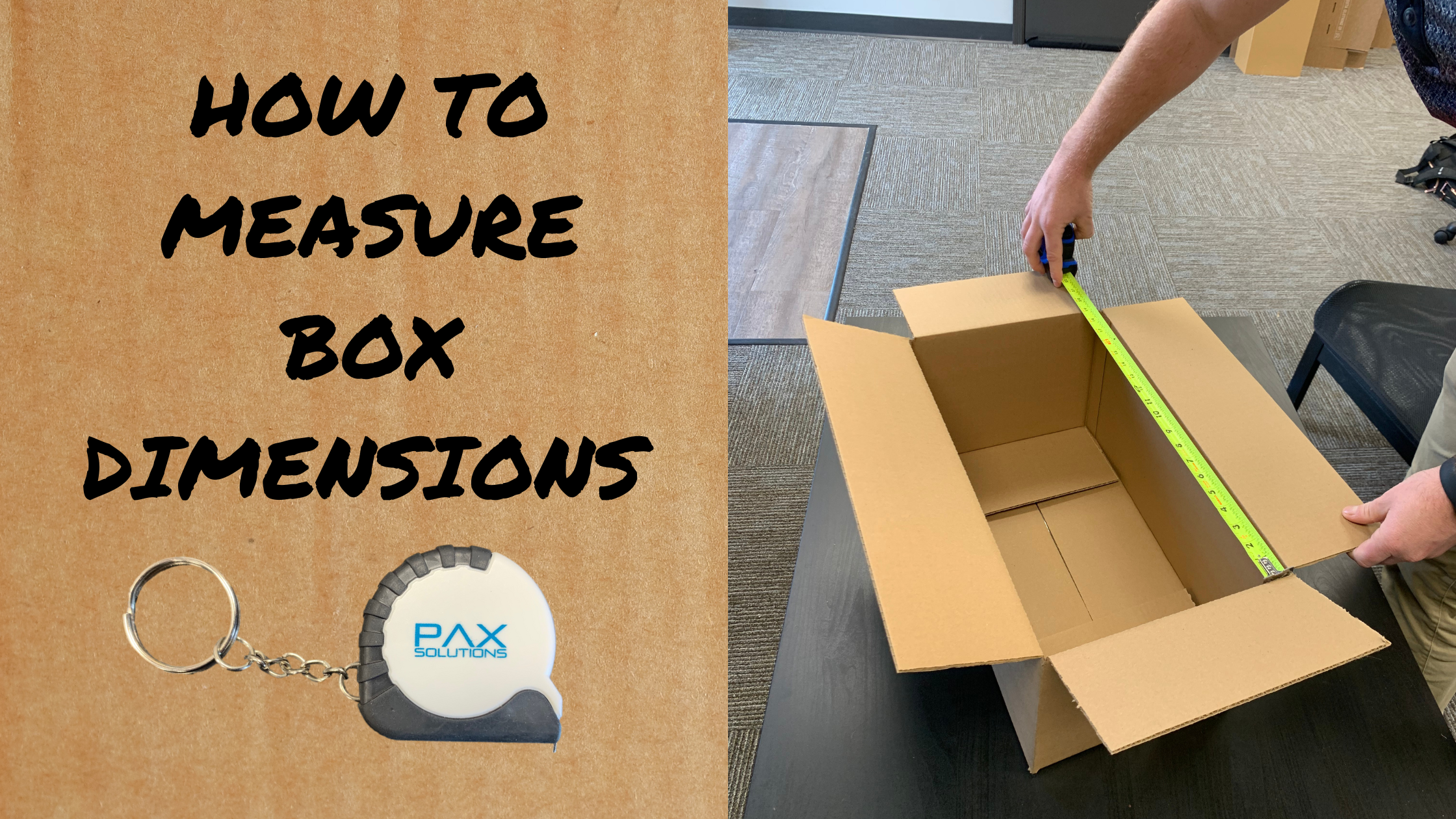

The Art of Measuring Box Dimensions: Ensuring Perfect Packaging Every Time

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

We respond fast! Please complete the form below and our team will contact you shortly.

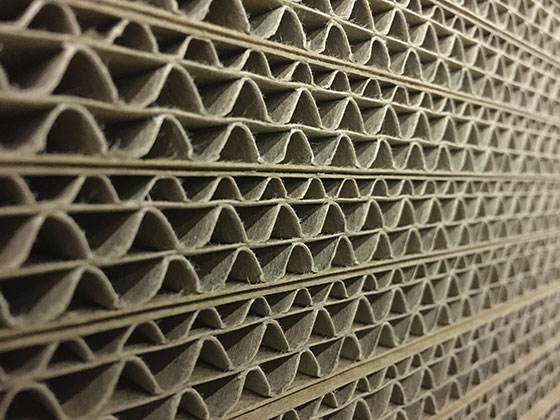

Corrugated packaging provides superior protection for your products during transit. The multi-layered structure absorbs shocks and impacts, minimizing the risk of damage and ensuring items reach their destination in pristine condition.

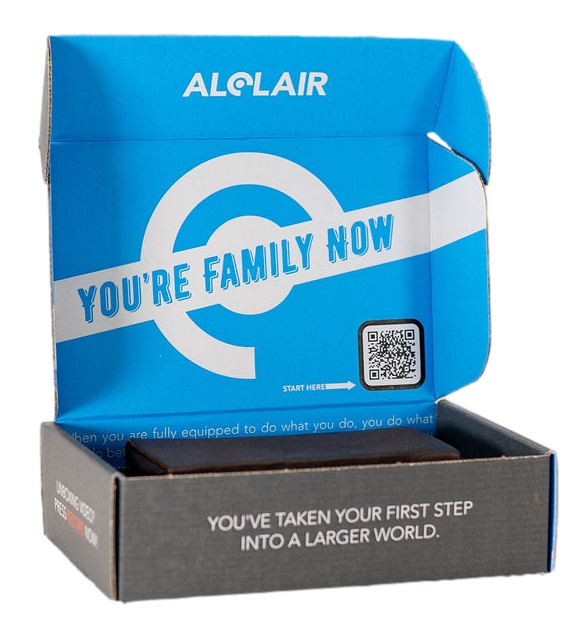

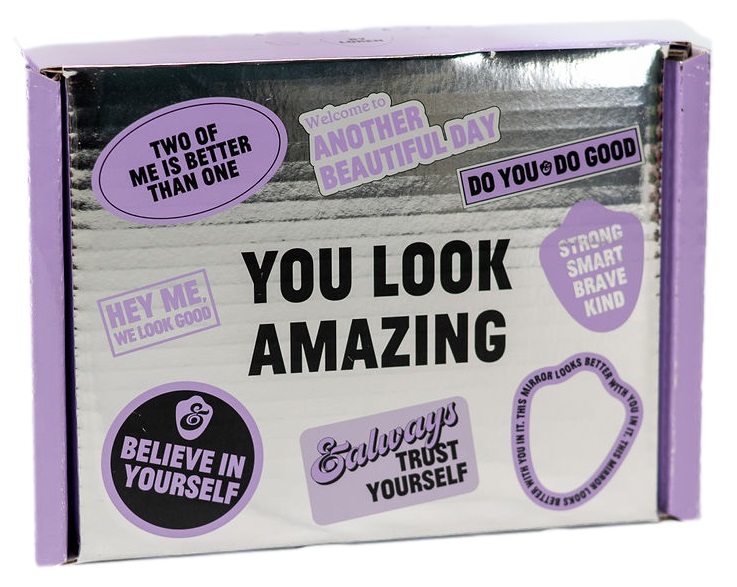

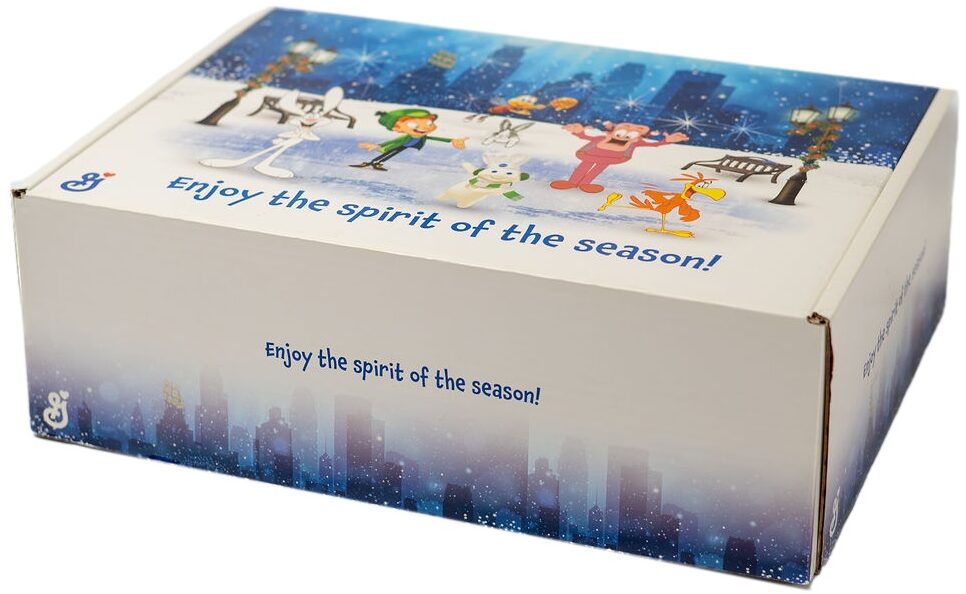

Corrugated boxes offer versatile design options, allowing for customization based on your specific branding and product requirements. From size and shape to printing and labeling, the flexibility of corrugated packaging ensures a tailored solution for all of your needs.

Not only is corrugated packaging easily recyclable and renewable, but it can also be reused as is, helping to further reduce packaging costs and the environmental impact. Many corrugated case styles are designed to be easily collapsible and fully reusable.

Corrugated packaging strikes a balance between affordability and functionality. The cost-effectiveness of these boxes, combined with their ability to protect products effectively, makes them an economical choice for businesses of all sizes.

Corrugated packaging is lightweight yet sturdy, making it easy to handle and store. Its easily stackable and optimizes storage space. Streamlined logistics and warehouse management by using corrugated packaging ultimately reduces your overall operational costs.

Corrugated packaging provides superior protection for your products during transit. The multi-layered structure absorbs shocks and impacts, minimizing the risk of damage and ensuring items reach their destination in pristine condition.

Corrugated boxes offer versatile design options, allowing for customization based on your specific branding and product requirements. From size and shape to printing and labeling, the flexibility of corrugated packaging ensures a tailored solution for all of your needs.

Not only is corrugated packaging easily recyclable and renewable, but it can also be reused as is, helping to further reduce packaging costs and the environmental impact. Many corrugated case styles are designed to be easily collapsible and fully reusable.

Corrugated packaging strikes a balance between affordability and functionality. The cost-effectiveness of these boxes, combined with their ability to protect products effectively, makes them an economical choice for businesses of all sizes.

Corrugated packaging is lightweight yet sturdy, making it easy to handle and store. Its easily stackable and optimizes storage space. Streamlined logistics and warehouse management by using corrugated packaging ultimately reduces your overall operational costs.

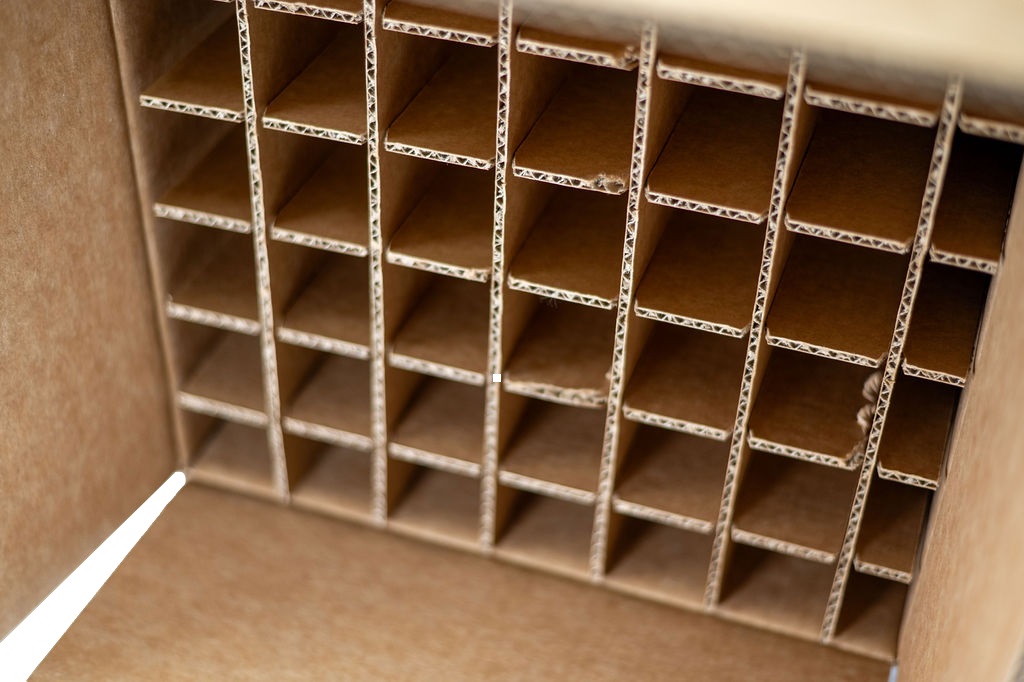

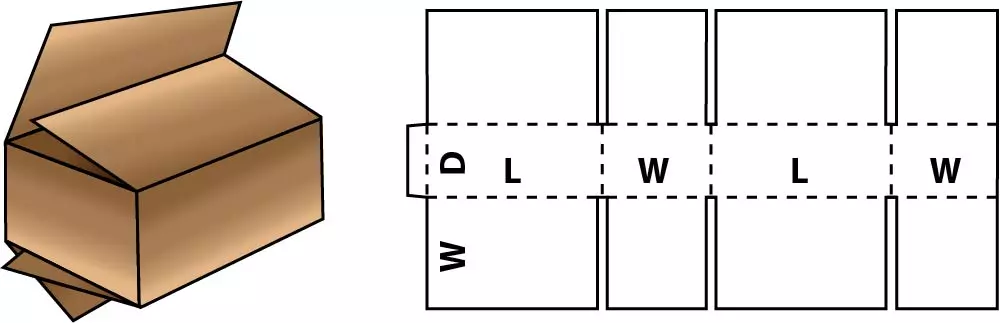

The applications for corrugated packaging are practically endless. With so much versatility, it is important to understand your options when determining the direction of your next project. – Below are some of the most common corrugated structures and solutions.

The FOL has flaps that extend and overlap each other covering the entire opening of the box. FOL boxes can be ordered with flaps just on top, just on the bottom, or on both top and bottom. This style provides additional strength to the ends of the box and can allow for easier assembly when dealing with smaller shipping boxes.

Die cut shippers require special tooling (referred to as cutting dies) to be manufactured. Different options are available depending on the project. The most common option is the front tuck shipper. This is a versatile shipping box that provides great protection. After the boxes are cut, they can be further customized by adding unique graphics or inserts to present the product.

FTD cartons consist of a separate top and bottom that fit over each other with flaps joining on the side or end panels. When pulled apart, they create two scored and slotted trays, both with flat bottoms. The full-depth cover slides completely over the body of the carton providing additional strength around the sides making this style suitable for high stacking strength of fragile articles.

Corrugated packaging is favored for its excellent structural strength and cushioning, providing reliable protection for goods during transit. It is also lightweight, which helps reduce shipping costs, and is highly customizable to various product dimensions.

Corrugated packaging is eco-friendly as it is primarily made from recycled paper. It is widely recyclable, contributing to a reduced environmental footprint by minimizing waste and promoting the reuse of materials.

Yes, corrugated packaging can be tailored to fit any size and shape, accommodating a range of products. This customization extends to the type of corrugation and the thickness of the board, allowing for enhanced protection as needed.

Not all corrugated boxes require cutting dies. Regular Slotted Containers (RSCs) typically do not need cutting dies, as they are folded from a single sheet of corrugated cardboard. However, die-cut boxes, which are custom-made for specific applications, do require cutting dies to achieve their unique shapes and features.

There are two primary types of printing used on corrugated packaging: direct printing and litho label printing. Direct printing involves printing the graphics directly onto the corrugated material, suitable for basic designs and bulk runs. Litho label printing, on the other hand, involves affixing a high-quality printed paper label onto the corrugated surface, offering superior image quality and finishing options for high-impact visual presentation.

Litho label printing is generally more expensive than direct printing due to the higher quality and complexity of the process. It is best used for products requiring high-resolution graphics or a more sophisticated packaging appearance. Direct printing is more cost-effective and is ideal for simpler designs and larger quantities where high-quality imagery is less critical.

More than 95% of all products in the United States are shipped in corrugated boxes because it is affordable, versatile, environmentally friendly, and provides great protection. Corrugated packaging is generally considered the most economical type of packaging. Custom printed corrugated boxes are an inexpensive and effective way to enhance your company’s brand, attract attention, and grow awareness.

Simply place your product inside and close the box!

Visit our PAX Solutions Blog to learn more about the fascinating world of packaging!

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

What Is Corrugate Fluting? Corrugated is a widely popular choice when it comes to packaging. Not only because of its

Corrugated packaging has had a profound impact on the world and the way we do business. Countless industries and business

Copyright 2024, PAX Solutions, All Rights Reserved