Embarking on a New Packaging Project: An 11 Step Guide

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

Dive into the world of foam packaging solutions, where protection meets precision. As a pivotal part in the packaging industry, foam packaging offers unparalleled cushioning, shock absorption, and protective properties. Its lightweight nature helps reduce shipping and handling costs while making sure the products inside the foam arrive safe and undamaged. With thousands of different foam material options, there is no doubt that foam packaging is here to stay and can be a great solution for your next protective packaging project.

Modern foam packaging solutions are increasingly focused on ecofriendly materials and recyclability to align with global efforts towards environmental responsibility. While many foam materials are yet to see sustainability improvements, we are seeing improvements in material sciences allowing for foam materials that are made of paper, plants, fungi, and other sustainable materials. As the foam packaging industry evolves, we expect to see further developments in ecofriendly foam options. Contact Us to speak with our experienced team for your next corrugated packaging project.

We respond fast! Please complete the form below and our team will contact you shortly.

Foam packaging offers superior cushioning and shock absorption protecting products against impacts and vibrations during transit. This ensures that even the most delicate items arrive in perfect condition, reducing the risk of damage and associated costs.

With numerous foam material options, designers have the freedom to select the perfect type of foam material based on the product’s weight, fragility, and level of protection required. From high-density foams offering robust support for heavy items to softer pliable foams ideal for delicate products, the right material choice ensures proper protection at a cost effective price point.

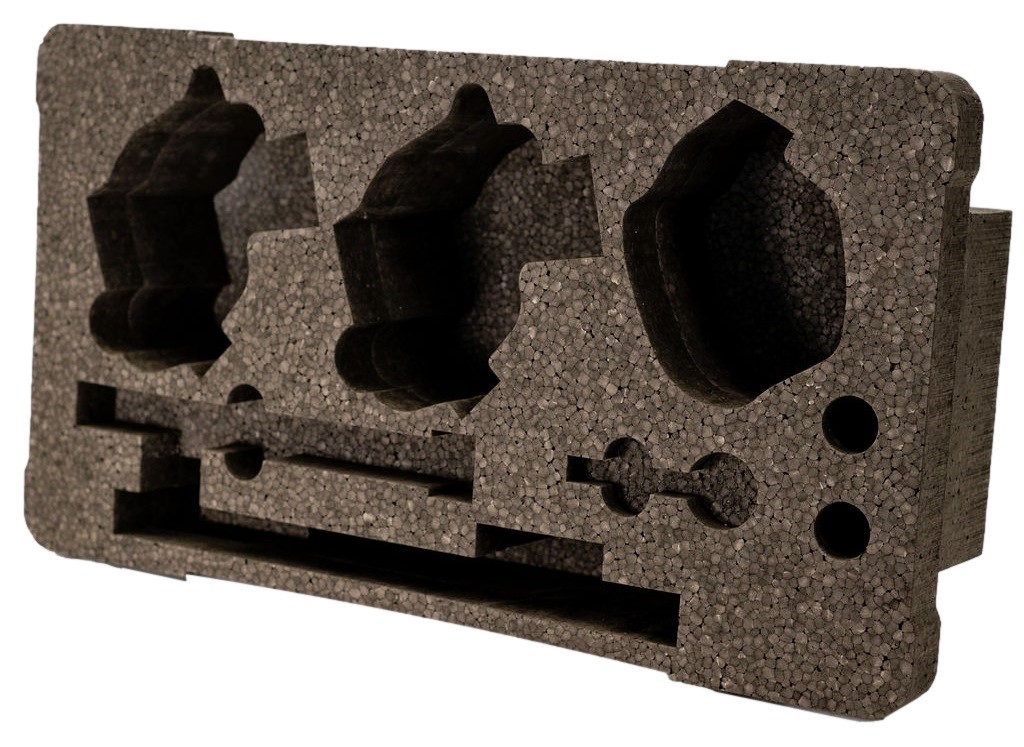

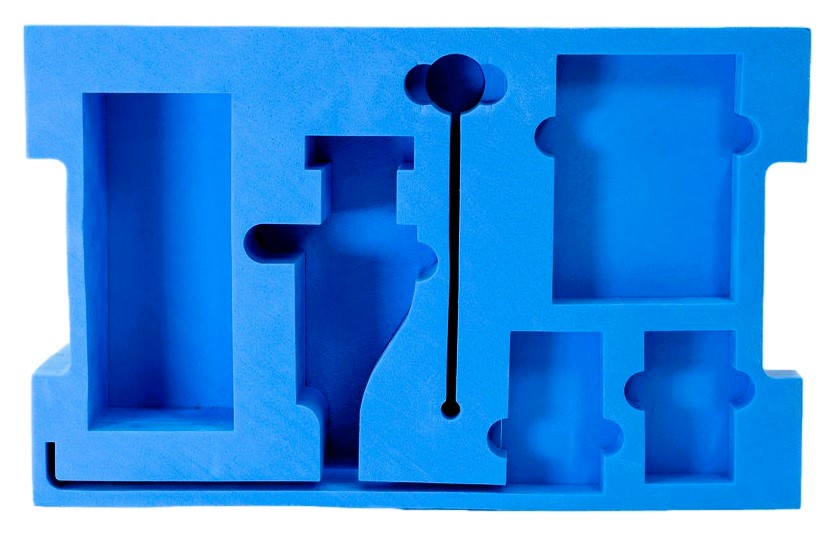

Foam packaging offers unparalleled versatility in engineering, allowing for custom designs that perfectly fit any product to ensure maximum protection in shipping and handling. This customization enhances overall product safety and quality while significantly improving packing efficiency to reduce both space and material waste.

Utilizing foam packaging safeguards the items without adding substantial weight to the packaging. This light-weight characteristic is particularly beneficial for parcel shipments where the weight of the package directly influences costs. Additionally, this helps reduce the environmental footprint by lowering fuel consumption during transit.

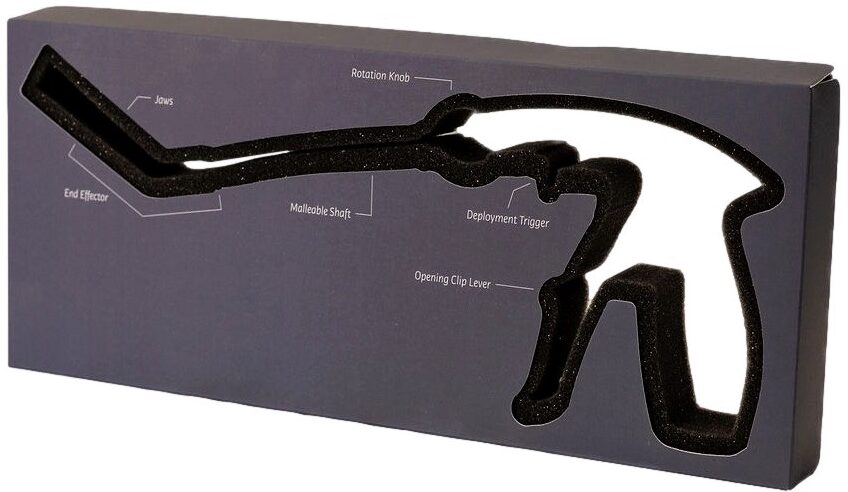

The customizability of foam packaging extends to its aesthetic appeal enabling companies to design unique and memorable packaging experiences. Its ability to be precisely cut and/or molded allows for a tailored fit that showcases the product during the unboxing process enhancing customer satisfaction and perceived value.

Foam packaging offers superior cushioning and shock absorption protecting products against impacts and vibrations during transit. This ensures that even the most delicate items arrive in perfect condition, reducing the risk of damage and associated costs.

With numerous foam material options, designers have the freedom to select the perfect type of foam material based on the product’s weight, fragility, and level of protection required. From high-density foams offering robust support for heavy items to softer pliable foams ideal for delicate products, the right material choice ensures proper protection at a cost effective price point.

Foam packaging offers unparalleled versatility in engineering, allowing for custom designs that perfectly fit any product to ensure maximum protection in shipping and handling. This customization enhances overall product safety and quality while significantly improving packing efficiency to reduce both space and material waste.

Utilizing foam packaging safeguards the items without adding substantial weight to the packaging. This light-weight characteristic is particularly beneficial for parcel shipments where the weight of the package directly influences costs. Additionally, this helps reduce the environmental footprint by lowering fuel consumption during transit.

The customizability of foam packaging extends to its aesthetic appeal enabling companies to design unique and memorable packaging experiences. Its ability to be precisely cut and/or molded allows for a tailored fit that showcases the product during the unboxing process enhancing customer satisfaction and perceived value.

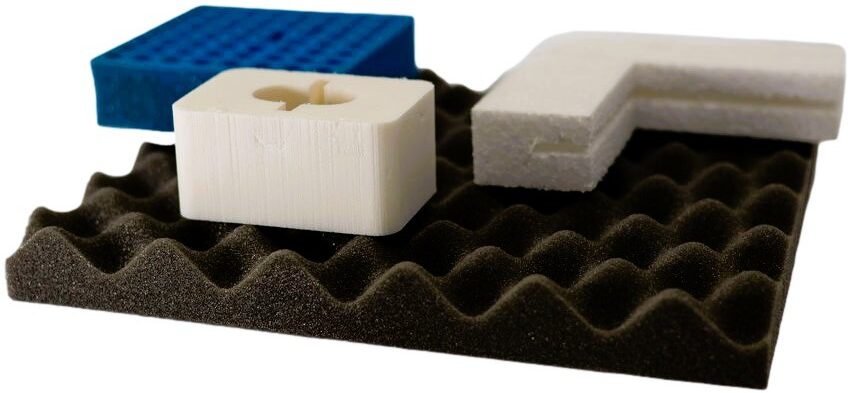

There are many different types of foam packaging materials that specialize in different aspects of packaging. Features of different foams include shock absorption, scratch/friction reduction, adhesive backing, anti-static, void fill, aesthetic value, and many others. Here are some of the more common foam materials used for foam packaging.

Polyurethane is a spongy open cell foam.

PU is ideal for products that require shock absorption and cushioning.

The surface of PU foam is nonabrasive and safe for contact with most surfaces.

PU foam comes in different densities which are used depending on the weight and size of the product being packaged.

Common colors are white or various shades of grey.

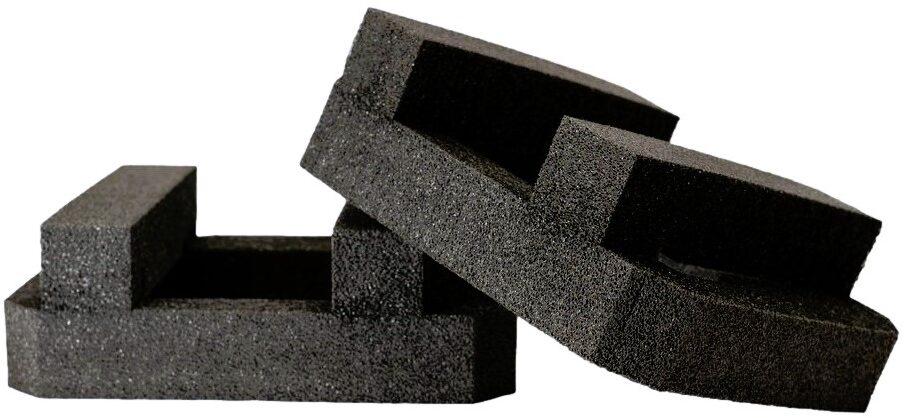

Polyethylene is a sturdy, resilient closed cell foam.

PE foam is ideal for products that require shock absorption, insulation, and vibration dampening.

The surface of PE foam is textured, so items that can scratch easily should not be packaged in direct contact of PE foam.

PE foam comes in different densities depending on the weight and size of the product being packaged.

Common colors are white or black.

Convoluted foam, also know as eggcrate foam, refers to the shape of the foam.

It can be manufactured using most foam materials, but PU and PE are the most common.

The peak-and-valley eggcrate appearance provides more cushion than other types of foam packaging and allows for increased air flow.

The shape helps the foam fill more internal space using less total material.

Expanded Polyethylene is closed cell beaded foam.

This foam is lightweight and performs the same, if not better, than standard PE foams.

Customers can use less foam material and still achieve great protection.

EPE offers protection for Class A surfaces meaning delicate surfaces, such as powder coated metals, will not scratch when in contact with EPE foam.

Common colors are white or black.

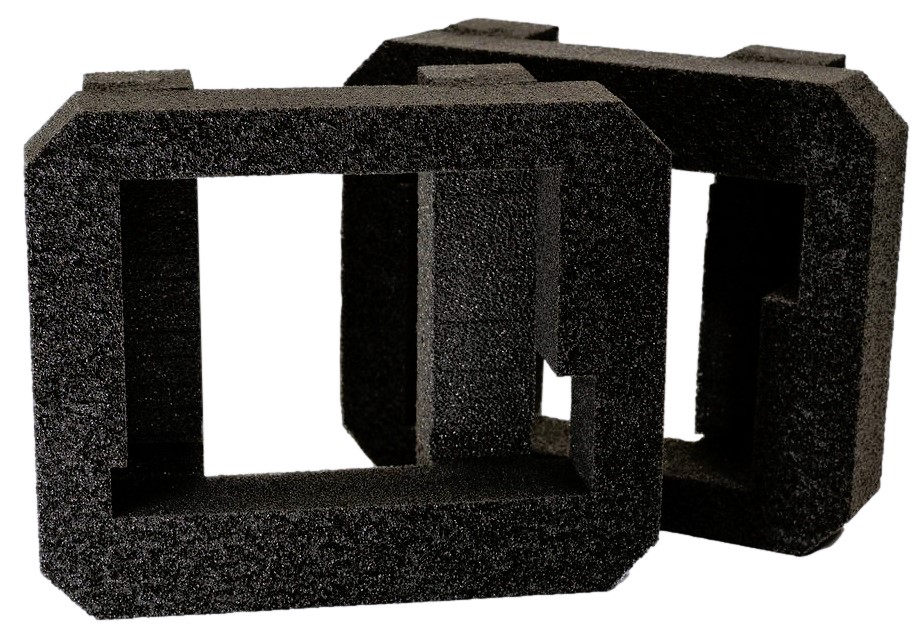

Crosslink foam is a high-end closed cell foam.

It is one of the more expensive foam options, but also very popular because it offers great protection and presentation.

Crosslink foam offers protection for Class A surfaces meaning delicate surfaces, such as powder coated metal, will not scratch when in contact with crosslink foam.

XLPE foam is very dense with a smooth, cleaning looking appearance.

Crosslink foam is commonly used in the medical industry because it is ozone resistant. XLPE foam comes in many different colors.

ESD Foam is comprised of three sub-categories: Conductive Foam, Static Dissipative Foam, and Anti-Static Foam. There are closed and open cell foam options available for all three categories.

The specific ESD properties of the product being packaged will determine which foam should be used for which applications.

Most anti-static foam is pink; however, all three sub-categories are available in various colors.

Foam packaging is ideal for fragile, sensitive, or high-value items that require extra protection, including electronics, medical equipment, delicate instruments, and luxury goods. Its versatility makes it suitable for a broad range of industries.

Yes, foam packaging can be precisely engineered to meet specific product dimensions and protection requirements. Customization options include various foam densities, shapes, and properties (such as antistatic or flame retardant) to ensure optimal protection.

Sustainability in foam packaging is increasingly prioritized, with options including recyclable materials, biodegradable foams, and designs that minimize waste. It is always important to select foams that align with your environmental goals.

Beyond protection, custom foam inserts can significantly enhance the unboxing experience by presenting products in an organized, visually appealing manner. This not only impresses customers but also reinforces brand quality.

The main advantages include excellent shock absorption, lightweight properties that reduce shipping costs, thermal insulation, and the ability to be tailored to any size or shape, providing a snug and secure fit for maximum product protection.

Choosing the right foam packaging involves considering the product’s weight, fragility, sensitivity to static electricity, and any specific handling requirements. Consulting with a packaging specialist can help identify the most suitable foam material and design for your needs.

Visit our PAX Solutions Blog to learn more about the fascinating world of packaging!

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

Contact Pax Solutions to learn more about cast and blown stretch film.

Contact Pax Solutions to learn more about on-demand void fill solutions.

Copyright 2024, PAX Solutions, All Rights Reserved