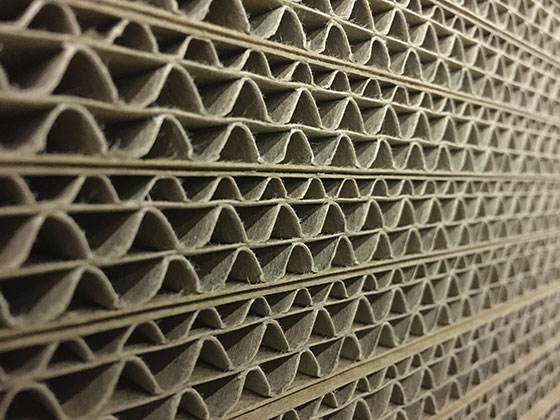

What Is Corrugate Fluting?

Corrugated is a widely popular choice when it comes to packaging. Not only because of its environmentally friendly status, but also because of its strength, low cost, and protective attributes. Corrugated is made from 3 layers of paper; a flat top and bottom layer know as the liner, and the corrugated fluting or “medium” which is composed of the wavy arch-like structures that give the corrugated its differentiating properties. These properties include:

Burst Strength: Pressure needed to rupture through corrugated

Stacking Strength: Weight that can be stacked on the corrugated

Bending Resistance: Pressure required to bend the corrugated

Impact Resistance: How much impact the box can take before failure

Cushioning & Shock Absorption: Refers to how much force the corrugated can absorb or mitigate

Tear Resistance: Force required to tear the corrugated

One way corrugated is classified is based on flute size. There are several different sizes of fluting. In general, the larger the flute size, the more strength and protection the corrugated will provide. Thinner flutes are lighter and typically less expensive because the thin flutes require less paper. Smaller flutes also provide a better printing surface when compared to larger flutes. This is because there are more flutes per linear foot which creates a more rigid, smooth, and consistent surface for printing.

Each flute size has its own function and features. Below is an overview of each flute highlighting some of its properties.

A Flute (1/4” Thickness)

The largest arch size and strongest performance of the corrugated fluting options. A flute corrugated provides an abundance of strength, cushioning, impact resistance. Because of this, it is commonly used to hold large and heavy items, or delicate items that need extra impact resistance and shock absorption during the shipping and handling processes. The extra protection does come at a cost; the large fluting requires more raw material because of the large arches. Therefore, A flute corrugated is generally one of the more expensive fluting options. There are 33 flutes per linear foot of A flute corrugated.

C Flute (3/16” Thickness)

The most common flute size as it has a great balance between cost and performance. Even though it is not the thickest flute size, it still provides adequate strength and impact-resistance for most applications. C flute also has a better surface for printing than A Flute, which allows for basic printing on the corrugated. C Flute is most commonly used for your standard regular slotted containers (RSC) because of its superior stacking and burst strength. There are 39 flutes per linear foot of C flute corrugated.

B Flute (1/8” Thickness)

The “Jack of all trades, master of none” of the corrugated industry. B flute corrugated has good strength and cushioning across the board, but A flute and C flute are better. B flute provides a good printing surface due to its smaller arch sizes, but E / F / G flute are technically better because of their even smaller arches. You can see where this is going… B flute is above average in most corrugated performance properties, but it is not #1 in any performance measure. That said, B flute is PAX’s Solutions favorite flute because of its flexibility and above average performance in all areas. There are 47 flutes per linear foot of B flute corrugated.

E Flute (1/16” Thickness)

One of the thinner flute options. E flute has several benefits because of its thin structure. At just 25% the thickness of C flute, storage and handling cost can be drastically reduced with E flute corrugated assuming your product does not need the additional protection offered by thicker flutes. E flute also provides great printability as the small flutes helps keep the board straight for consistent printing. E flute is best used for packaging smaller, light weight items that are not easily breakable. There are 90 flutes per linear foot of E flute corrugated.

F Flute & N Flute (1/32” Thickness & 1/51” Thickness)

Also known as micro flutes, F and N flute are the thinnest flute options in the corrugated packaging industry. They use less fiber and have smaller arches to create a robust, puncture-resistant box. In addition, they are also crush resistance due the small, already compact arches. Its printing surface also allows for more elaborate printing applications than some of the other flute options. Micro flutes are not commonly available in all parts of the world; when available, it is used mostly for retail packaging. F flute has 125 flutes per linear foot. N flute has 170 flutes per linear foot.

Are you looking for guidance on your next corrugated project? Contact PAX Solutions and experience the best service in the industry!