What is lamination?

Lamination applies a thin layer of plastic to paper or corrugated material to enhance and protect printed packaging. Types of laminations include glossy, matte, silk type, and scuff-proof. Lamination is used for a variety of printed items including but not limited to packaging, book covers, brochures, and business cards. When used for packaging, it can give the logos and print a crisp, visually appealing image increasing a consumer’s interest in the product.

Lamination Types

Below are pictures and descriptions of common types of laminations to allow you to find the lamination that suits your packaging needs.

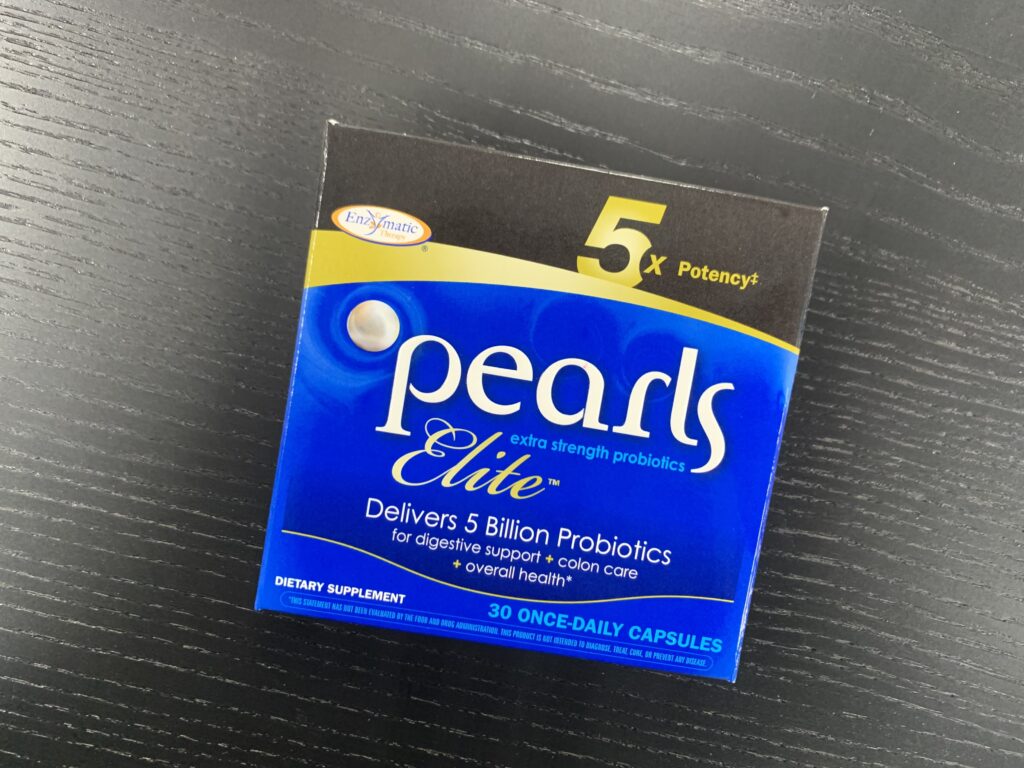

Glossy Lamination

Gloss lamination causes your text and images to appear, sharper and crisper while allowing for more contrast in colors. This makes gloss a popular choice for its visual appeal.

Additionally, gloss lamination is the durable choice. Not only does it have qualities to repel dirt, dust, and fingerprints, it easily wipes clean without causing damage to the packaging.

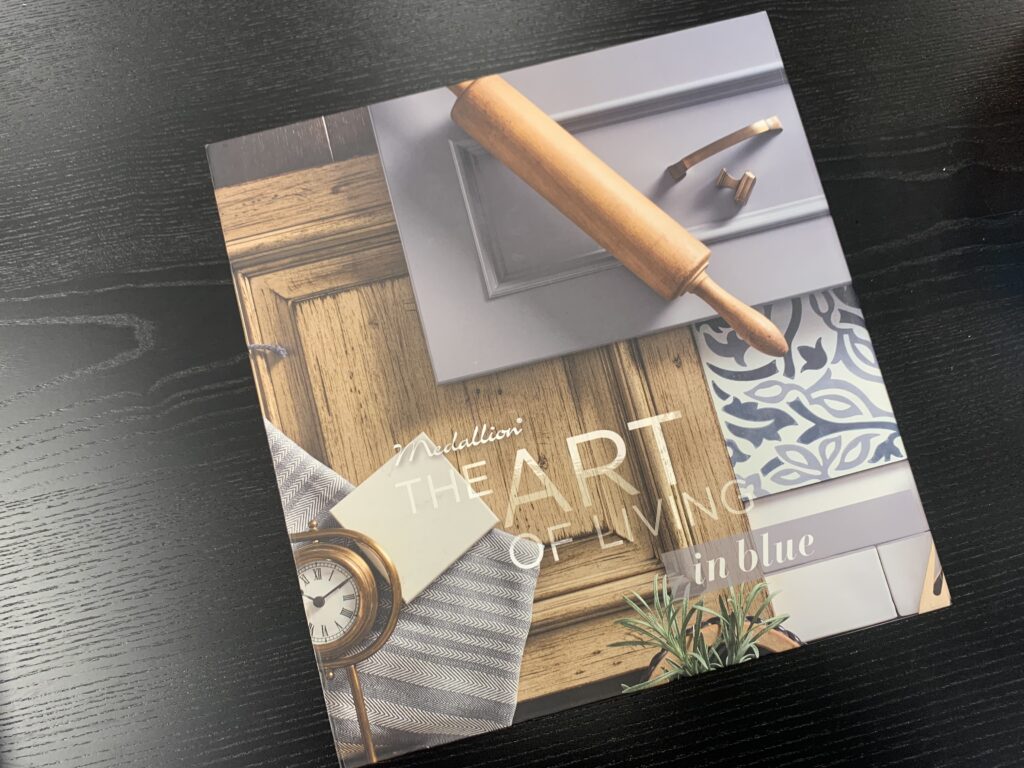

Matte Lamination

Matte lamination provides a natural, elegant, and sophisticated finish. Matte lamination provides a softer look than gloss lamination, producing less contrast in darker colors.

Matte finish gives your packaging a velvety texture.

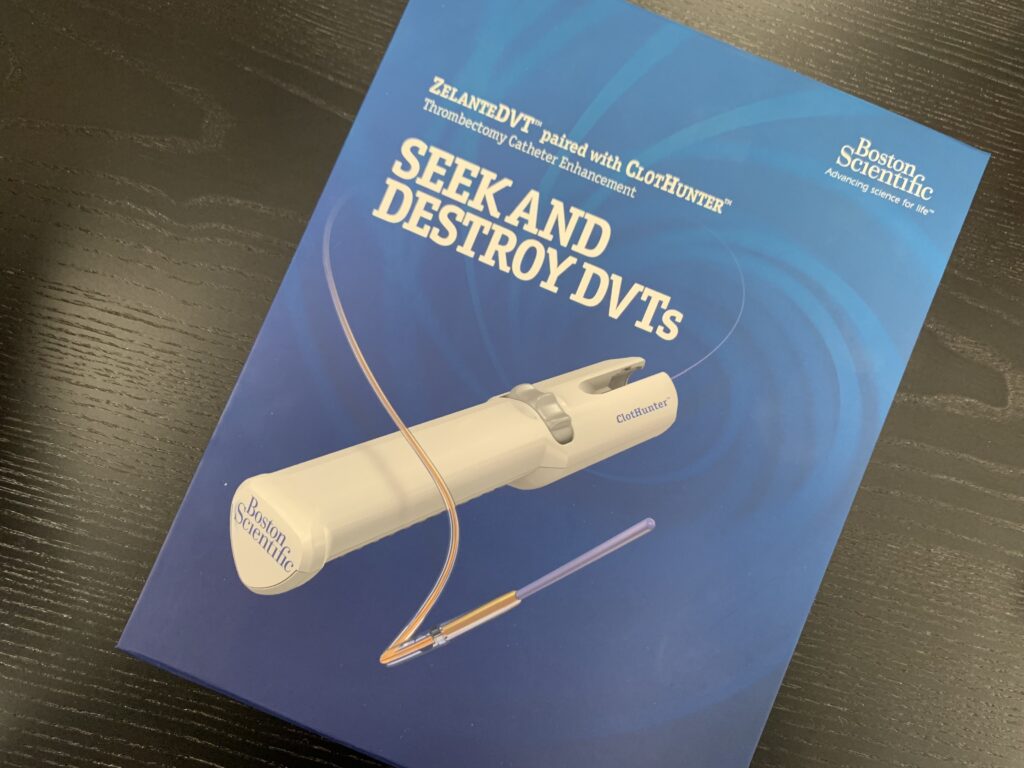

Softtouch Lamination

Softtouch lamination looks similar to a standard matte finish, but adds extra depth, appealing to the sense of touch. The smooth feel creates a luxurious experience for anyone holding your packaging.

The material is not fully matte or glossy but reflects in certain lights. The premium finish makes the packaging more attractive, as the finish is smooth and natural looking.

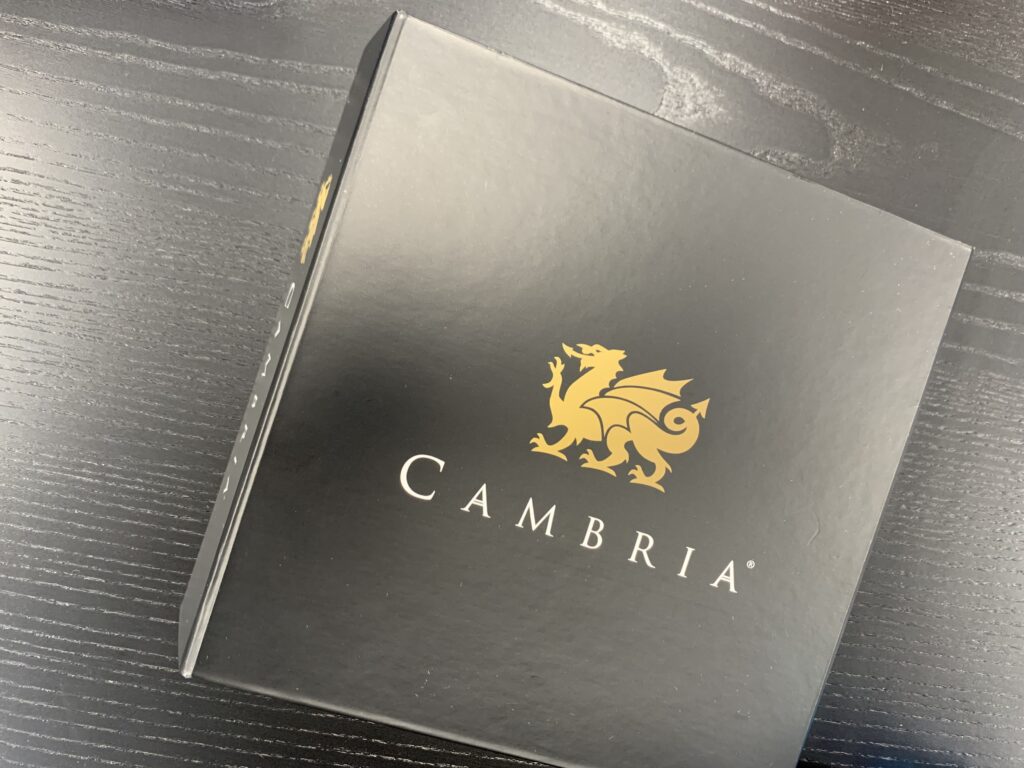

Scuff-proof Lamination

Scuff-proof lamination is typically matte. This lamination boasts an extreme hardness level providing an ultra-smooth, ultra-protective surface. This film provides excellent resistance to unwanted scuff marks that could develop during production, transportation, and handling of the package.

This durable lamination is a good fit for frequently handled packaging and marketing kits. Scuff-proof also works well over darker printed packaging because dark packaging tends to show scratches more than lighter colors.

Matte, glossy, soft touch, and scuff-proof lamination offer many benefits for packaging. These include:

- Durability. Laminated packaging has increased strength and rigidity allowing it to withstand shipping and high levels of use for packaging that is meant to be kept and store product.

- Protection. Lamination protects the packaging against damage from fingerprints, liquid spills, stains, grease, dirt and more. If the laminate does get dirty, it is easy to clean.

- Enhanced visual and tactile appeal. Enhanced ink colors create a more professional look. The added strength and rigidity of the laminated packaging gives the impression of higher quality.

- Readability. As it is completely transparent, lamination does not damage or spoil the print and can provide better contrast between colors allowing for increased readability.

- Increased quality. Lamination saves money by extending the life of the packaging with increased quality.

Which industries are a good fit for laminated packaging?

Lamination is used for packaging in a number of industries not limited to:

- Medical

- Marketing

- Personal care

- Cosmetics

- Food & Beverage

- Candle

- Giftables

- Educational materials

- Printed materials

Frequently asked questions about lamination

Why should I laminate my packaging?

Lamination finishes offer many advantages such as tear-resistance, durability, and water-resistance. Laminating materials also makes them easier to handle and prevents wear and tear like wrinkles, stains, and sun damage. Lastly, lamination adds to the overall quality and presentation of the packaging.

What is the cost to laminate my packaging?

Cost to laminate packaging depends on the material on which the lamination process is to be applied, size, and type of lamination.

The advantage lamination brings to your packaging is easily worth the small increase in price.

What type of lamination should I use?

The choice between lamination types depends on the printed piece and its intended use. All types provide strong, clear coverage that makes text and graphics fully visible to the reader and increases durability.

Understand that matte absorbs light while glossy reflects it. This makes a significant difference in the finished look so it’s important to use the type that fits your packaging goals.

Matte lamination is recommended when:

- You want to deflect glare, making the packaging piece easier to read at an angle.

- The packaging will not be handled frequently as matte laminates can easily scratch or scuff with heavy use.

- You want a modern, sophisticated look.

- Print has subdued color tones.

Glossy lamination is recommended when:

- The packaging is handled frequently. Gloss provides more protection than matte and is easier to clean if needed.

- You want the packaging to have a strong visual impact. With gloss lamination, the colors will pop off the page.

Take a look at our packaging galleries to see different applications for lamination in packaging.

Make contacting PAX Solutions one of your first steps when researching lamination for your next packaging project. By contacting PAX Solutions early in the project design phase, we can provide design insight, budgetary estimates, structural samples, and overall packaging guidance. PAX Solutions will make sure your next project gets done right and creates that WOW factor to help grow your business!