Embarking on a New Packaging Project: An 11 Step Guide

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

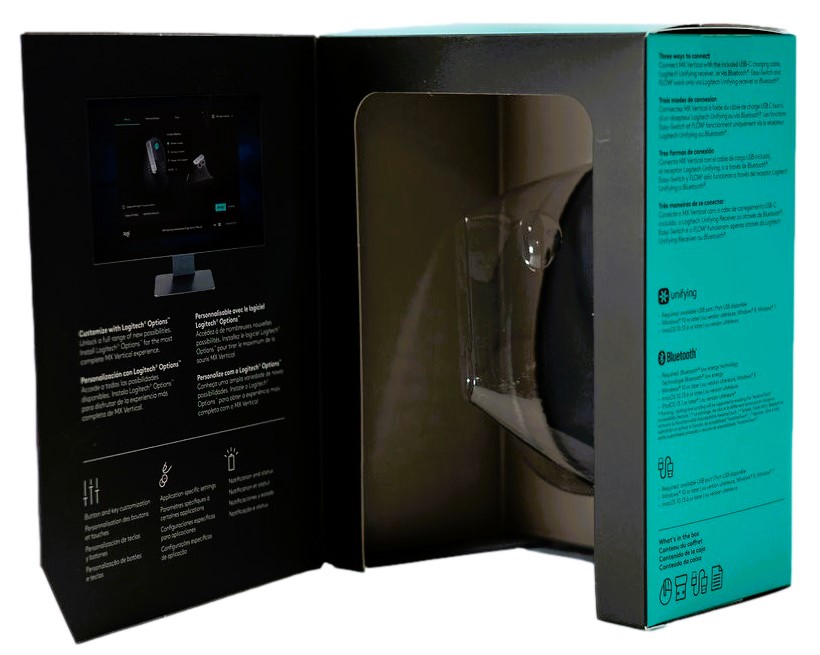

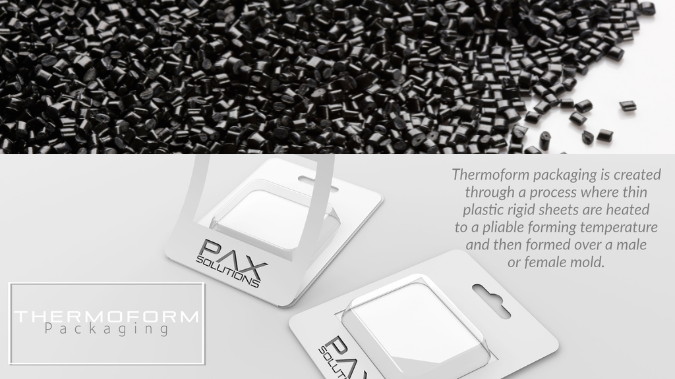

Thermoform packaging stands out for its exceptional ability to protect products in transit and storge while offering unparalleled versatility and cost efficiency. When properly designed to meet the rigorous demands of modern distribution channels, thermoform packaging encases products in custom fit cavities make from durable, lightweight materials. Not only does this ensure the packaged items arrive to their destination in good condition, but the overall presentation and unboxing experience conveys quality, thoughtfulness, and intention.

The strength of thermoform packaging lies in its customizability, allowing for the creation of packaging solutions that are perfectly customized to the shape, size, and sensitivity of each product. Depending on the type of material and material gauge, thermoform packaging provide a protective barrier against shocks, vibrations, impact, and external pressures extending the lifespan of the product. Integrating thermoform packaging into the supply chain represents a strategic investment in product integrity, perceived value, and brand reputation. Contact Us to speak with our experienced team for your next corrugated packaging project.

We respond fast! Please complete the form below and our team will contact you shortly.

The streamlined production process of thermoform packaging allows for high-volume runs at a lower cost unit price compared to other types of protective packaging. By precisely molding the thermoform material to the shape of the product, you eliminate excess space and material waste leading to significant cost savings in both production and shipping.

Thermoform packaging stands out for its unparalleled design flexibility, enabling the design of custom shapes, cavities, and features that perfectly hold virtually any product. This enhances the aesthetic appeal and functionality of the package ensuring every item can be organized and securely packaged.

The inherent lightness of thermoform packaging materials contributes to efficient handling and reduced transportation emissions, aligning with corporate sustainability commitments. Despite their minimal weight, these materials provide robust protection ensuring products reach their destination safe and secure.

Thermoform packaging is well suited for automation, allowing for seamless integration into high-speed packing lines significantly increasing efficiency and reduced labor costs. The uniformity and precision of thermoforming promotes reliable processing and minimizes equipment downtime.

The strength and stability provided by thermoform packaging safeguards products during transit and storage effectively extending product shelf life. Thermoform packaging excels in its ability to withstand significant wear and tear reducing the need for replacement and additional packaging.

The streamlined production process of thermoform packaging allows for high-volume runs at a lower cost unit price compared to other types of protective packaging. By precisely molding the thermoform material to the shape of the product, you eliminate excess space and material waste leading to significant cost savings in both production and shipping.

Thermoform packaging stands out for its unparalleled design flexibility, enabling the design of custom shapes, cavities, and features that perfectly hold virtually any product. This enhances the aesthetic appeal and functionality of the package ensuring every item can be organized and securely packaged.

The inherent lightness of thermoform packaging materials contributes to efficient handling and reduced transportation emissions, aligning with corporate sustainability commitments. Despite their minimal weight, these materials provide robust protection ensuring products reach their destination safe and secure.

Thermoform packaging is well suited for automation, allowing for seamless integration into high-speed packing lines significantly increasing efficiency and reduced labor costs. The uniformity and precision of thermoforming promotes reliable processing and minimizes equipment downtime.

The strength and stability provided by thermoform packaging safeguards products during transit and storage effectively extending product shelf life. Thermoform packaging excels in its ability to withstand significant wear and tear reducing the need for replacement and additional packaging.

The least expensive option which is primarily used for small parts and shipping trays. PVC has high chemical resistance, good stiffness and impact strength, and naturally flame retardant. Its properties do not work well for certain applications such as medical because of its relatively poor barrier against moisture ingress and oxygen ingress. Common industries and uses include: machine shops, work-in-progress trays, handling trays, consumer goods, display cases, marketing kits, blister packs, storage bins.

Great option for optics, medical trays, and other various medical applications. PETG comes in many different thickness options. This material has excellent strength, good clarity, chemical resistance, and overall outstanding thermoforming characteristics. Common industries and uses include: medical trays, medical clamshells, POP displays, signs, machine guards, consumer goods, electronics, display cases, marketing kits, blister packs.

Commonly used for disposable foodservice applications. PETG offers many great characteristics such as high chemical resistance, good clarity, easily moldable, inexpensive, and high electrical and heat resistance. Polystyrene is also easily recycled. One disadvantage of PS its low hardness and impact strength, meaning it can crack or break easier than other thermoform materials. Common industries and uses include: disposable cups, disposable applications, electrical application, POP displays, signs, electronics, foodservice applications, disposable shipping trays.

Compared to Polystyrene (PS), HIPS trades off the natural clarity offered by PS for greatly improved impact resistance and hardness. Similar to PS, HIPS has other advantages such as chemical resistance, dimensional stiffness, and moldability. HIPS is recyclable although the process is uneconomical. Common industries and uses include: consumer food containers, foodservice applications, POP displays, clamshell packaging, signs, consumer goods, bottles, shipping trays, reusable trays, picture frames.

Commonly used for medical applications because of its unique chemical resistance properties and high heat deflection. Polypropylene material can withstand sterilization processes like autoclave. PP has a high level of stiffness but is not that hard making it susceptible to scratching or chipping. Common industries and uses include: medical trays, medical clamshells, dental trays, dental clamshells, food containers, consumer goods, shipping trays, storage trays.

Engineered plastic that can have customized characteristics. ABS has good baseline impact strength, stiffness, and hardness as well as other beneficial properties such as heat deflection. It is cost effective but more expensive than PS, PVC, or PETG. Common industries and uses include: POP displays, signs, tool cases, automotive applications, consumer goods, storage trays, storage cases.

Thermoform packaging is generally more cost-effective for high-volume production runs due to its low material costs and fast production times. The initial setup costs can be higher due to mold design and creation, but these are often offset by the savings in large-scale production.

Yes, thermoform packaging can be recycled, depending on the type of plastic used. Common materials like PET (polyethylene terephthalate) and PVC (polyvinyl chloride) are recyclable. However, recycling facilities’ acceptance of these materials can vary, so it’s important to check local guidelines.

Absolutely. Thermoform packaging is commonly used for food products as it can be made from food-grade materials that meet safety standards, providing an airtight environment that extends shelf life and protects against contamination.

Yes, custom labels can be made waterproof and weatherproof by selecting appropriate materials, such as vinyl or polyester, and finishes, ensuring durability in various environments.

Yes, there are several ways to design thermoform packaging with sustainability in mind, including using recycled materials, minimizing material usage in the design phase, and selecting materials that are readily recyclable within most municipal recycling programs.

Thermoform packaging offers extensive customization options, including the shape and size of the packaging, the type of plastic material used, and the addition of features like snap closures or perforations for easy opening. It can also be designed to enhance the product display or include branding elements.

Visit our PAX Solutions Blog to learn more about the fascinating world of packaging!

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

Contact Pax Solutions to learn more about thermoform trays, blister packs, and clamshell packaging options.

Contact Pax Solutions to learn more about on-demand void fill solutions.

Copyright 2024, PAX Solutions, All Rights Reserved