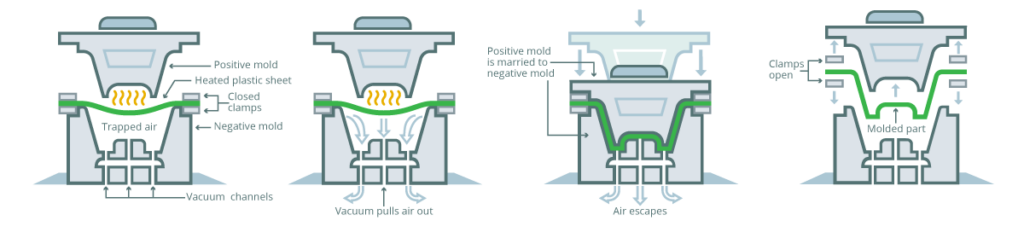

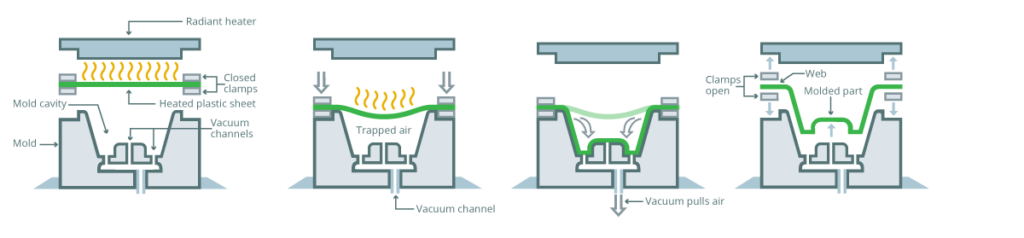

Thermoforming is a process of heating a thermoplastic sheet to its softening point. The sheet is then stretched across a single-sided mold and then manipulated using machine assist (mechanical thermoforming) or vacuum assist (pressure thermoforming) force to push the hot material into the mold of desired shape. The mold is generally made of aluminum for durability and ease of use, however 3D printed molds have become a popular choice in recent years. Once cool, the resulting thermoformed tray is custom to the exact item it was made for.

Mechanical Thermoforming

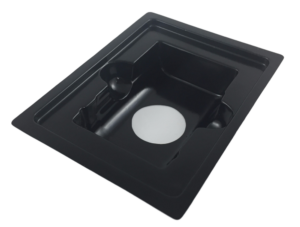

Mechanical thermoforming is when a positive space mold is pressed into the soft heated plastic. The resulting negative space shape is the final shape of the thermoformed item.

Pressure Thermoforming

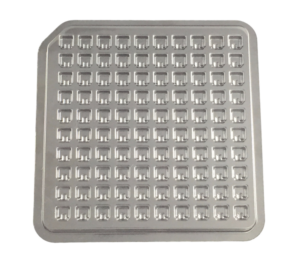

Pressure, or vacuum, thermoforming uses negative pressure to pull (or vacuum) the soft heated plastic into the resulting shape.

Why Use Thermoform Packaging?

When used for packaging, thermoformed plastic can be used to create highly customized trays, clamshell packaging, and blister packs. Thermoforming is a very accurate process allowing cavities to be designed with clearance areas for fragile and sensitive components. Common industries that utilize thermoformed packaging are food & beverage, confectionery, cosmetics, medical device, fishing lures, and small parts. Any product that should be protected from getting crushed or squished or could puncture a carton or soft package will travel safely in a custom thermoformed package.

Additionally, if your product is better understood to the retail consumer when visible rather than pictured or explained on a box, clear thermoform packaging allows the consumer to view your product while it stays protected in the package. Retail features such as hang-holes and formed feet can be included in the clamshell design allowing the package to either hang or stand on a shelf.

Materials Used for Thermoforming

There are over 14 different types of plastic and plastic subcategories that can be used for thermoforming and each one is best for different applications. Different materials offer the following combination of qualities. The application in which you use thermoform packaging will determine which of these properties are best suited for your project.

- Stiffness

- Harness

- Impact Strength

- Flame Retardant

- Chemical Resistance

- Moisture and Oxygen Barrier

- Moisture and Oxygen Ingress

- Clarity

- Moldability

- Price

- Electrical Resistance

- Heat Resistance

- Recyclability

- Ability to Withstand Sterilization Processes

- Anti-static

But wait... There's More!

Visit our thermoform packaging page for an in-depth review of thermoform packaging and materials available. There you’ll learn more about the history of thermoforming (spoiler alert: the inspo came from turtle shells!), read through descriptions of the available materials, and discover the best material and shape for your application or industry.

When you’re ready, contact PAX Solutions to help you find the perfect solution for your business today!