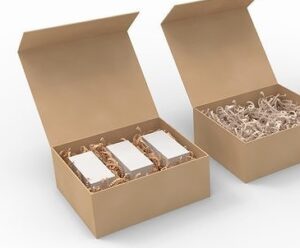

When designing packaging it is important to consider how you will pack your product in the container to keep it from moving around and becoming damaged. Depending on your product, empty, or void spaces may be present. There are many void fill options available depending on your needs and budget. Below are void fill supply options that don’t require any upfront equipment or investment.

Packing Paper

Packing paper is perhaps the most conventional material to use when filling voids in packaging. There are many reasons why it has stood the test of time. The first and perhaps the most appealing is that it is recyclable. With the growing demand for environmentally friendly options, packing paper will continue to see use now and well into the future. You can easily form it into the shape you need, and it is generally inexpensive depending on the type of paper used. Packing paper is good for fragile items as it is gentle on surfaces, highly malleable, and absorbs impact well. The main drawback to packing paper is that it requires a large amount to actually protect your product from most damage. It also does not provide as much protection quality as foam or bubble wrap.

Bubble Wrap

Bubble wrap is another common packing material. It is made from plastic and uses little “air pockets” to provide protection from rough handling. These air pockets usually provide adequate protection of the product and they are very lightweight, so they do not add a lot of expense to your overall shipping costs. This is a great benefit that a lot of companies look for. Bubble wrap does however take up a large amount of space and it can be time consuming to cut it, wrap it around the product, and in some cases secure it with tape. Bubble wrap is also made from plastic, making it less environmentally friendly than some of the other options, and with the growing trend of eliminating plastic that is something to consider.

Packing Peanuts

Packing peanuts are small “peanut” shaped pieces made from starch or polystyrene. Like bubble wrap, they are very lightweight which helps with shipping costs, and they do a good job at protecting the product. Depending on the type of packing peanut, this can also be an environmentally friendly option as well. For instance, the starch version of packing peanuts is biodegradable. Packing peanuts are able to settle in and fill all void spaces allowing them to fit and protect all shapes of products, but in many cases this requires a lot of packing peanuts. They also have a low presentation quality and tend to create a mess.

Crinkle Paper

Crinkle paper is made of paper and can come in many fun, brand-themed colors. This makes it not only a great environmentally friendly option, but it also can create a fun unboxing experience for the consumer. Crinkle paper is essentially shreds of paper, so it can hold almost any size or shape. This is great for when you want to package multiple items, or if the item going into the box has an odd shape to it. Like packing peanuts, you usually must use a large amount to make sure the items are protected, and can create a mess, but many consumers will repurpose the crinkle paper for crafts or bedding for small animals.

Convoluted Foam

Convoluted foam, or “egg-crate foam”, is created with peaks and valleys to provide rigidity and reduce cost compared to solid foam. The most common use of convoluted foam is to “sandwich” the item that is to be protected. Convoluted foam provides a quality feel and luxurious, clean appearance. While convoluted foam may be a more costly option when it comes to void fill, it provides the highest level of protection to the product it is holding. With all packaging, you will want to consider the product’s value and what it would cost if the product was damaged versus the cost of void fill material. For more valuable items, convoluted foam is a preferred choice.

While all the above void fill options are great choices because they are readily available options, sometimes custom made void fill is a better choice depending on the product. In our next blog, we explain why “on-demand” and custom void fill options might be a better option for your needs. Contact PAX Solutions for guidance on which void fill option is best for your packaging needs.

While all the above void fill options are great choices because they are readily available options, sometimes custom made void fill is a better choice depending on the product. In our next blog, we explain why “on-demand” and custom void fill options might be a better option for your needs. Contact PAX Solutions for guidance on which void fill option is best for your packaging needs.