Embarking on a New Packaging Project: An 11 Step Guide

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

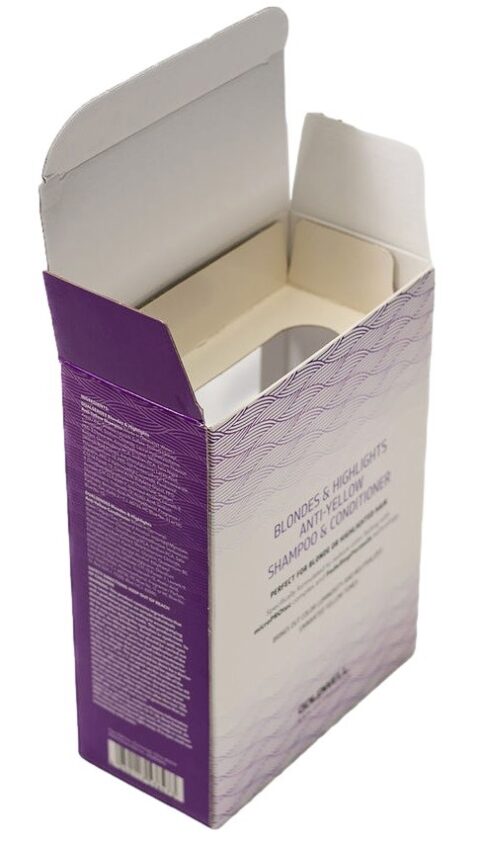

Discover the sleek and sophisticated world of folding carton packaging where elegance meets functionality! With many unique printing and branding options, folding cartons are a great way to speak to your customers and elevate the product experience. Its versatile nature allows for creative branding opportunities and structural designs that can be customized down to the smallest detail. Considering that folding cartons are one of the most eco-friendly and sustainable packaging options, it’s no surprise that folding cartons have come to dominate the world of custom product packaging.

With today’s rapidly changing retail and online distribution channels, folding cartons have continued to be a staple for branded packaging. Its lightweight yet protective properties help companies keep their costs down while providing product distinction. While there are many folding carton designs that are optimized for hand-loading such as auto-bottom folding cartons, there has also been numerous developments in loading your products through automated equipment further reducing your true packaging costs and allowing for high-volume product output. Contact Us to speak with our experienced team for your next corrugated packaging project.

We respond fast! Please complete the form below and our team will contact you shortly.

With supply chains have become global and more complex, folding carton packaging remains an efficient solution to get your products in customer’s hands. Folding cartons provide effective protection considering its light-weight nature while helping keep shipping and handling costs low.

Folding carton packaging transforms every product into a beacon of brand identity and customer impact. If used correctly, this can be a strategic tool to support your overall marketing strategy.

When it comes to custom product applications, folding carton packaging excels in its ability to offer unique, product-specific solutions to elevate the customer unboxing experience.

When it comes to custom product applications, folding carton packaging excels in its ability to offer unique, product-specific solutions to elevate the customer unboxing experience.

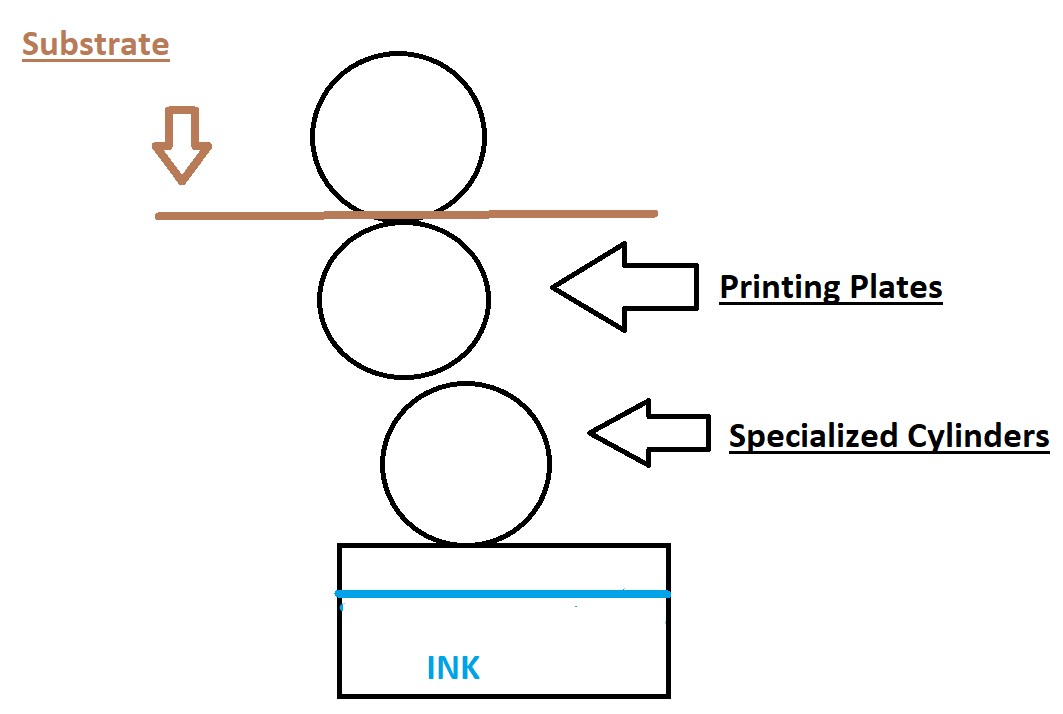

Folding carton packaging leverages advanced printing technologies allowing for high-end graphics and vibrant colors making your packaging stand out from the competition. Constant improvements to lithography, flexography, and digital printing have allowed folding carton packaging to stay relevant in our ever- changing economy.

With supply chains have become global and more complex, folding carton packaging remains an efficient solution to get your products in customer’s hands. Folding cartons provide effective protection considering its light-weight nature while helping keep shipping and handling costs low.

Folding carton packaging transforms every product into a beacon of brand identity and customer impact. If used correctly, this can be a strategic tool to support your overall marketing strategy.

When it comes to custom product applications, folding carton packaging excels in its ability to offer unique, product-specific solutions to elevate the customer unboxing experience.

When it comes to custom product applications, folding carton packaging excels in its ability to offer unique, product-specific solutions to elevate the customer unboxing experience.

Folding carton packaging leverages advanced printing technologies allowing for high-end graphics and vibrant colors making your packaging stand out from the competition. Constant improvements to lithography, flexography, and digital printing have allowed folding carton packaging to stay relevant in our ever- changing economy.

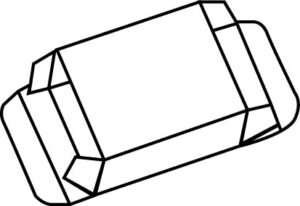

Selecting the right folding carton design is a key factor when developing folding carton packaging. Product size, shape, and weight are all important factors to consider along with manufacturing and automation processes. Below are some of the most common folding carton structures and designs.

Straight tuck end cartons are constructed with each end folding and locking on the same side.

The STE can provide better graphics presentation because both tucks are positioned at the back of the box giving the front of the carton a clean distraction-free appearance.

A fifth panel can be added to the carton to create a hang hole or provide additional space for graphics.

Common industries: custom vitamin / supplement packaging, custom pharmaceutical packaging, custom perfume packaging, custom food packaging, custom retail packaging, custom nutraceutical packaging, custom soap boxes, custom CBD oil packaging, custom e-liquid packaging, custom confectionery packaging, custom essential oil packaging, and custom beard oil packaging.

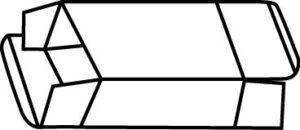

Reverse tuck end cartons are constructed like the STE carton, but the tucks are reversed and lock on opposite sides.

The main advantage of the RTE vs. STE is lower unit cost because the RTE can be printed more efficiently on a press sheet.

Essentially, the reverse tuck end design sacrifices the clean frontal presentation the straight tuck end carton offers in exchange for a lower unit price.

Common industries: custom candy packaging, custom vitamin / supplement packaging, custom pharmaceutical packaging, custom perfume packaging, custom food packaging, custom nutraceutical packaging, custom retail packaging, custom soap boxes, custom CBD oil packaging, custom e-liquid packaging, custom essential oil packaging, and custom beard oil packaging.

Tuck top auto bottom cartons are used in many different applications because they can be assembled and loaded quickly by hand.

As the name states, the top of the chipboard box tucks into the carton to secure the product and the bottom is automatically formed when first erecting the carton.

Common industries: custom food packaging, custom retail packaging, custom cosmetic packaging, custom nutraceutical packaging, custom personal care packaging, custom medical packaging, custom biotech packaging, custom sporting goods packaging, and custom electronics packaging.

Tuck top snap lock bottom cartons are the same as the tuck top auto bottom cartons with the exception that the bottom does not come pre-glued.

The snap lock bottom, also referred to as a 1-2-3 bottom, consists of four flaps that are folded and locked together to form the bottom of the chipboard box.

The image below illustrates how the 1-2-3 bottom is constructed to form the bottom of the box. The snap lock bottom is stronger than the auto bottom and less expensive to manufacture; the trade-off is longer time to assemble compared to the auto bottom carton.

Common industries: custom food packaging, custom retail packaging, custom cosmetic packaging, custom personal care packaging, custom medical packaging, custom biotech packaging, custom sporting goods packaging, custom nutraceutical packaging, and custom electronics packaging.

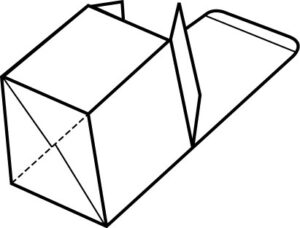

Tuck top rolled end cartons are unglued boxes that must be folded and assembled prior to placing the product inside.

The sides with the rolled edges have three total layers of board for added strength.

The image below illustrates how the rolled end tuck top carton is folding into a box. It also shows the tuck top that is present in many folding carton styles.

A panel can be added to the front of the box that folds back into the inside creating cavities for the product or additional marketing space.

Common industries: custom food packaging, custom retail packaging, custom cosmetic packaging, custom gift packaging, custom personal care packaging, custom medical packaging, custom biotech packaging, custom nutraceutical packaging, custom sporting goods packaging, and custom electronics packaging..

Folding cartons are chosen for their cost-effectiveness, lightweight nature, and excellent printability, which makes them perfect for branding and detailed graphic designs. They are also easily customizable, recyclable, and suitable for automated packing lines.

Folding cartons are highly sustainable as they are typically made from renewable resources and are recyclable, often part of a closed-loop recycling process which reduces waste and environmental impact.

Folding cartons support a wide array of printing options, including digital, offset, and flexographic printing, as well as a variety of finishes such as matte, glossy, UV coating, and foil stamping to enhance the visual appeal.

Absolutely, folding cartons are suitable for food products as they can be made with food-grade materials and coatings that comply with health and safety regulations, ensuring the packaging is safe for direct food contact.

Lead times can vary depending on the complexity and quantity of the order, but typically range from a few weeks to a couple of months. It’s best to consult with your packaging provider for precise timelines.

Folding carton packaging is generally more cost-effective due to its simpler manufacturing process, less material waste, and its lightweight nature which saves on shipping costs.

Visit our PAX Solutions Blog to learn more about the fascinating world of packaging!

Contact Pax Solutions for expert guidance and help when starting your next custom packaging project!

Rigid setup boxes and folding cartons are some of the most popular box choices in the packaging world when it

A great way to upgrade your packaging is through high quality print design. It can turn an average looking box

Copyright 2024, PAX Solutions, All Rights Reserved